An axle counter consists of a sensor, which detects the individual axles of a practice by mechanical, electrical or even fibre optic method, and an evaluator which counts the axles passing into and out of a rail part. They are used in application for counting, classification (velocity and axle), weigh-in-motion, tolling and even regulation enforcement installations comparable to speed and red gentle working. The circuit is one in all six application concepts contained in National Semiconductor's knowledge sheet for the LMC835 c-mos graphic equalizer with digital control in puts. Typically a class I sensor is used for weigh-in-movement application whereas class II sensors are used to gather axle classification data. When utilizing wireless GNOM axle masses sensor with BLE, driver can carry out onboard weighing during cargo loading and thus prevent exceeding axle load restrict. An axle counter sensor includes two impartial sensors (so the machine can detect the course and velocity of a train by the order and time through which the sensors are handed). Piezo Sensors are an axle detection sensor that is installed in the roadway (mostly everlasting however might be non permanent).

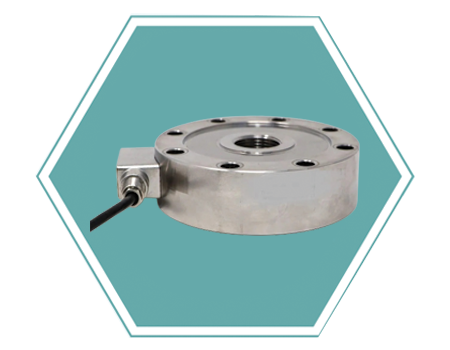

The technician goes to car, connects to CAN bus and reads the info looking for obligatory CAN parameters. Still, data presence can't be determined prematurely and must be confirmed by set up technician. Thru-hole load cells supply distinctive versatility and will be utilized for both tension and compression measurements. 6. Packaging: The packaging industry uses SBO Series load cells to observe and control the filling and sealing processes of packages. For instance, High Speed Load Cell a load cell may measure the tension on a machine that winds cabling on a spool to make sure the system uses a constant tension throughout its process. Rail yard management software program uses occupancy information from the axle counters to lock switches and forestall vehicles from being routed to tracks which can be occupied by other automobiles. Many weighbridges are actually linked to a Pc which runs truck scale software program capable of printing tickets and providing reporting options. Who is Accountable for Paying Overweight Tickets in Canada & the USA? Pressure sensor measures the pressure within the vehicle pneumatic system and transmits data as an analog signal to telematics terminal. GNOM will send data to a telematics unit and to driver’s smartphone concurrently - axle load information will likely be available in smartphone app.

Allows axle load knowledge monitoring by way of BLE on smartphone (wireless GNOM sensors). The axle counter sensors are either connected to the evaluator by way of devoted copper cable or by way of a telecommunications transmission system. Axle counters are significantly helpful on electrified railways as they get rid of the need for traction bonding and impedance bonds. Axle counters require no bonding and fewer cabling in comparison to track circuits, and are subsequently typically cheaper to install and maintain. Axle counters are immune to these issues because they don't rely on the contact of wheel with the rail head to provide an electrical circuit. Piezo sensors work by producing a sign (voltage and present) when an axle/tire comes in contact with them within the roadway, This signal is detected by the electronics in a counter/classifier. That’s why touching the cable changed the contact resistance and negatively affected the indicator worth. I do not need acccuracy, just a tough worth. Axle counters are also helpful on long sections where the need for several intermediate observe circuits could also be saved.

Axle counters are also useful on steel constructions (such as the Forth Bridge), which may prevent the normal operation of monitor circuits if insulating the rails from the construction proves impracticable. The stress is measured on each sides of the orifices throughout operation to verify choking. Pressure sensor GNOM DDE is used to determine the axle load in vehicles outfitted with air suspension in transport telematics systems. Calibration of sensor and telematics unit configuration are required. Axle counters are positioned on the monitor before each switch and on every track that exits the swap. Axle counters remove most railjoints (IRJ) which are a weak level on the observe. Load cells for cranes are tools that converts the pressure of the load into an electrical signal that can be interpreted by a show or controller. The evaluator might also convert the analogue signal of the axle sensor into a digital signal. Because the prepare passes an analogous axle counter sensor at the top of the part, the system compares depend at the tip of the part with that recorded at the start.

Axle counters are also useful on steel constructions (such as the Forth Bridge), which may prevent the normal operation of monitor circuits if insulating the rails from the construction proves impracticable. The stress is measured on each sides of the orifices throughout operation to verify choking. Pressure sensor GNOM DDE is used to determine the axle load in vehicles outfitted with air suspension in transport telematics systems. Calibration of sensor and telematics unit configuration are required. Axle counters are positioned on the monitor before each switch and on every track that exits the swap. Axle counters remove most railjoints (IRJ) which are a weak level on the observe. Load cells for cranes are tools that converts the pressure of the load into an electrical signal that can be interpreted by a show or controller. The evaluator might also convert the analogue signal of the axle sensor into a digital signal. Because the prepare passes an analogous axle counter sensor at the top of the part, the system compares depend at the tip of the part with that recorded at the start.

Comments

Post a Comment